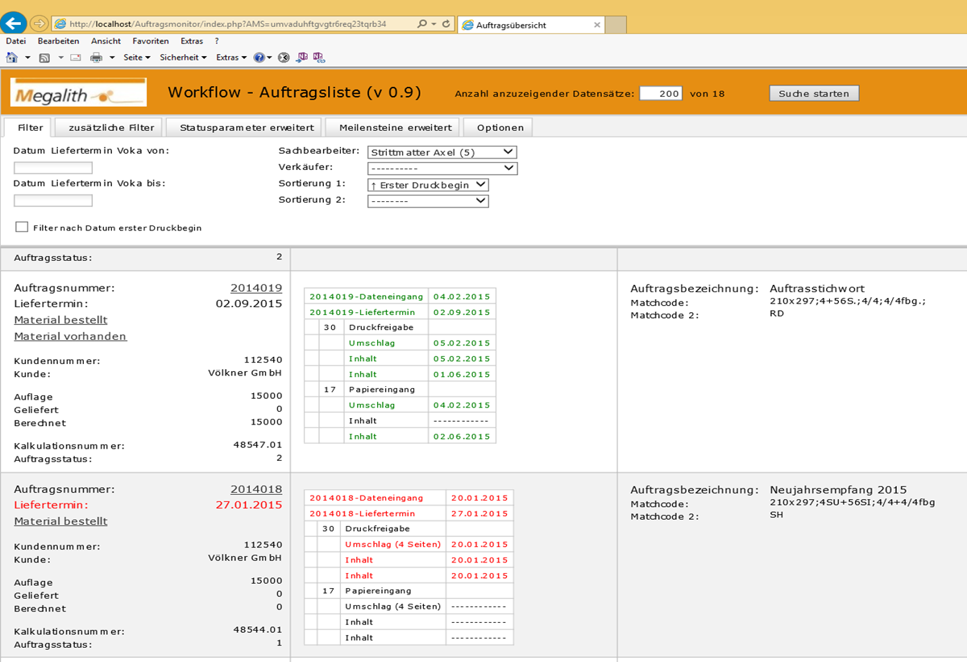

Job monitor

The MEGALITH job monitor is the instrument for editing and monitoring all jobs.

All incoming jobs can be managed using the job monitor.

The job monitor is the control centre for the sales team for job processing.

Using function buttons, the job monitor gives fast access to:

- Log in/ordering job-related material and paper

- Basic date notification for scheduling (e.g. planed data delivery, planned printing release, planned printing approval, etc.)

- Retrieval of the paper status of the job

- Retrieval of the production status of the job

- Insights into concurrent accounting

- An overview of planned and completed deliveries

- Overview of the status of the pre-print stage (response via JDF/JMF)

- Overview of capacity of production